Bottle Packaging Machine

Bottle Packaging Machine Specification

- Features

- Corrosion Resistant, Safety System, User-friendly Interface

- Power Supply

- AC

- Application

- Bottle Filling and Packaging

- Filling Range

- 50 ml to 2000 ml

- Usage

- Used in beverage, pharmaceutical, chemical industries

- Noise Level

- Low

- Type

- Bottle Packaging Machine

- Material

- Stainless Steel

- Auxiliary Packaging Machine Type

- Multi-Function Packaging Machines

- Capacity

- 2000-3200 bottles/hour

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Power

- 3 Kw

- Voltage

- 220V / 380V

- Weight (kg)

- 850 kg

- Dimension (L*W*H)

- 2300mm x 950mm x 1500mm

- Color

- Silver

- Sealing Type

- Automatic Cap Sealing

- Maintenance Requirement

- Low, easy-to-remove parts for cleaning

- Label Application

- Front, Back and Wrap-around

- Compressed Air Requirement

- 6 Bar

- Conveyor Speed

- Adjustable, up to 20 m/min

- HMI Display

- 7-inch Touchscreen

- Operating Temperature

- 5-45°C

- Changeover Time

- < 15 minutes

- Bottle Shape Compatibility

- Round, Square, Custom

- Lubrication

- Centralized Auto Lubrication

- Bottle Material Supported

- Glass, PET, HDPE

- Safety Features

- Emergency Stop, Overload Protection

Bottle Packaging Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 30 Pieces Per Month

- Delivery Time

- 1-2 Days

About Bottle Packaging Machine

Bottle Packaging Machine Features:

- High tensile strength

- Sturdy construction

- Easy installation

- Longer service life

Adaptable Packaging for Every Requirement

Designed for maximum versatility, the Bottle Packaging Machine supports a wide range of bottle shapes and materials. From small pharmaceuticals to large beverage bottles, its adjustable conveyor, multi-format label application (front, back, and wrap-around), and rapid changeover makes it perfect for businesses with diverse product lines.

Superior Performance and Durability

Engineered with high-grade stainless steel, this machine withstands demanding industrial environments. Its streamlined design includes features like centralized auto-lubrication, overload protection, and a low-maintenance structure, ensuring long life and reliable operation even with intensive usage.

Efficient and User-Friendly Operation

The machine integrates a PLC-based control system and a 7-inch touchscreen interface for easy setup and monitoring. Safety features such as emergency stop and overload protection, combined with a quiet noise profile and fast maintenance access, prioritize user safety and operational convenience.

FAQs of Bottle Packaging Machine:

Q: How does the machine adapt to different bottle shapes and sizes?

A: This Bottle Packaging Machine is engineered to handle round, square, and custom-shaped bottles. With adjustable guides and programmable settings on the touchscreen HMI, operators can quickly switch between different bottle formats within 15 minutes without the need for extensive retooling.Q: What materials can be used with this packaging machine?

A: The system is compatible with glass, PET, and HDPE bottles. Its equipped to manage various material thicknesses, making it suitable for a diverse range of products in beverage, pharmaceutical, and chemical industries.Q: When is the best time to perform maintenance on the machine?

A: Thanks to its centralized auto-lubrication and easy-to-remove parts, maintenance is minimal and quick. Regular cleaning can be carried out during standard downtime, and scheduled inspections based on usage keep the machine performing optimally.Q: Where can the Bottle Packaging Machine be installed?

A: Its compact footprint and robust design (2300mm x 950mm x 1500mm) make it suitable for installation in production floors of beverage plants, pharmaceutical manufacturing units, chemical processing lines, and other industrial settings across India and globally.Q: What is the label application process like on this machine?

A: This machine supports front, back, and wrap-around label applications. The PLC control system ensures precise labeling while adjustable conveyor speed allows synchronization with various production lines for seamless packaging.Q: How does the safety system benefit operators?

A: Equipped with an emergency stop switch and overload protection, the machine offers enhanced operator safety. The robust safety systems ensure quick response in case of issues, protecting both personnel and equipment during operation.Q: What are the benefits of using this bottle packaging machine?

A: Users gain from high-speed, fully-automatic operations, low maintenance, and flexible configuration, resulting in greater productivity, reduced manual intervention, and reliable packaging quality. Its corrosion resistance and easy-to-clean parts ensure longevity and hygiene for demanding industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Automatic Pouch Packaging Machines Category

Aluminium Foil Sealing machine

Price 15000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic Grade : Automatic

Feature : Other, LeakProof Sealing, HighSpeed Operation, Durable Structure

Type : Other, Aluminium Foil Sealing Machine

Material : Stainless Steel, Aluminium

Detergent Cake Packing Machinery

Price 650000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Feature : Other, Corrosion Resistant, High Speed Operation

Type : Other, Automatic Detergent Cake Packing Machinery

Material : Stainless Steel

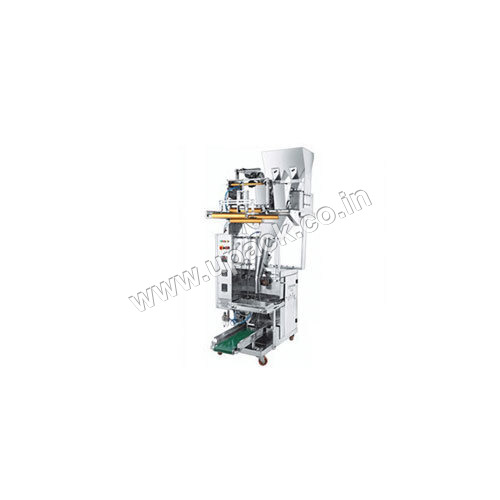

Two Head Weigher Pneumatic Machine

Price 550000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Material : Stainless Steel

Pouch Packaging Machine

Price 250000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic Grade : SemiAutomatic

Feature : Heavy Duty Machine, Durable

Type : Packaging Line

Material : Stainless Steel