MultiHead Collar Weigher Machine

MultiHead Collar Weigher Machine Specification

- Power Supply

- Single Phase

- Features

- Easy to operate, low maintenance, multi-language touch screen

- Noise Level

- <70 dB

- Filling Range

- 10 gm 1000 gm

- Application

- Food, Pharma, Chemical, and Agricultural Products

- Usage

- Ideal for automatic weighing and packaging

- Type

- MultiHead Collar Weigher Machine

- Material

- Stainless Steel

- Feature

- High Precision Weighing

- Auxiliary Packaging Machine Type

- Automatic Weighing Machine

- Capacity

- 60-120 bags per minute

- Computerized

- Yes

- Automatic Grade

- Fully Automatic

- Control System

- PLC Controlled

- Drive Type

- Electric

- Power

- 2.5 kW

- Voltage

- 220 V

- Weight (kg)

- Approx 550 kg

- Dimension (L*W*H)

- 1850 x 1300 x 1650 mm

- Color

- Silver

- Sealing Type

- Heat Sealing Compatible

- Film Pulling Mechanism

- Servo Motor Driven

- Bag Length

- 60-300 mm

- Safety Protection

- Interlock Safety Doors, Emergency Stop

- Compatible Products

- Rice, Pulses, Sugar, Chips, Namkeen, Pasta, Beans, Candy, Granules

- Feeding System

- Vibratory Feeder

- Cleaning

- Easy Openable and Removable Parts for Hygiene

- Weighing Accuracy

- ±0.2 to 1.0 g (depending on product)

- Display

- Touch Screen HMI

- Number of Weighing Heads

- 10/14 heads (as per model)

- Operating Temperature

- 5°C - 40°C

- Bag Width

- 70-200 mm

- Packaging Material

- Heat Sealable Laminate, OPP/CPP, OPP/PE, PET/FOIL/PE

- Main Motor

- Panasonic / Delta Servo Motor

MultiHead Collar Weigher Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Jaipur

- Payment Terms

- Cheque, Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 20 Pieces Per Month

- Delivery Time

- 5-6 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- Main Domestic Market

- All India

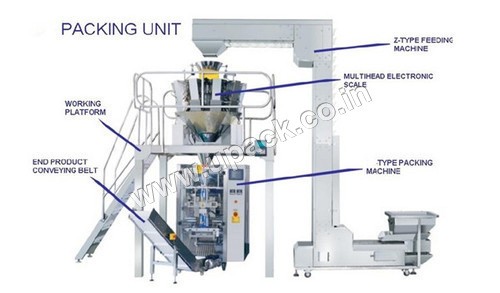

About MultiHead Collar Weigher Machine

To retain our goodwill in clients' consideration, we are manufacturing an excellent range of FFS With Multihead Weigher Machine.

Technical Specifications:

Features of FFS With Multihead Weigher Machine:

- Long working life

- Smooth operations

- Less maintenance

Technical Specifications:

- Packing Range: 10gm to 1kg

- Filling System: (Multi Head Weigher) 10 Head weigh Filler & 14 Head

- Type of Sealing: Center Seal

- Packing Material: Kurkure, Puffs, Potato Chips, Grains etc.

- Film Size: 100mm-500mm width x 100mm-200mm length

- Film Roll Type: Laminated Film in Roll Supported Film E.g. Aluminum Foil Pe

- Speed: 45 to 60 bag/min (Varies with the nature of product & filling range)

- Power: 3kw 230v / AC / Single Phase / 50hz

- Optional: Batch Coding Device, Batch Cutting Device Auto Lubrication, GMP Model, Gas Flushing Unit Level Sensor

- Wooden Case: 1300mm x 1000mm x 1000mm (H x W x L)

- Machine Size: 72" x 85" x 126

- Weight: 1400kg (Approx)

Advanced Touch Screen Control

The machine features a multi-language touch screen HMI for intuitive operation and easy parameter adjustments. This user-friendly interface streamlines setup, monitoring, and production changes, reducing downtime and improving efficiency during packaging runs. With computerized controls, operators experience seamless management and greater process oversight.

Exceptional Weighing Accuracy and Speed

Equipped with premium Panasonic or Delta servo motors, the machine offers weighing accuracy from 0.2 to 1.0 grams. The vibratory feeder and multiple weighing heads enable rapid processing of 60120 bags per minute. This ensures consistent, high-quality packaging for products such as rice, sugar, pulses, candies, chips, and more.

Flexible Application and Easy Maintenance

Compatible with various bag sizes and heat-sealable laminates, the machine suits multiple industries. Its easy-removal parts facilitate quick cleaning and maintenance, while safety features like interlock doors and emergency stops guarantee operator protection. The machine sustains reliable operation within a 5C40C working environment.

FAQs of MultiHead Collar Weigher Machine:

Q: How does the MultiHead Collar Weigher Machine ensure accurate and efficient weighing?

A: The machine employs advanced servo motors and multiple weighing heads (10 or 14, depending on the model) to deliver high-speed and precise weighing, with an accuracy range of 0.2 to 1.0 grams. The vibratory feeder system ensures even product distribution, maximizing both accuracy and speed for each batch.Q: What types of products and packaging materials can be used with this machine?

A: This machine is suitable for a variety of products, including rice, pulses, sugar, chips, namkeen, pasta, beans, candy, and granules. It accommodates heat-sealable laminate packaging materials such as OPP/CPP, OPP/PE, and PET/FOIL/PE, making it versatile for food, pharma, chemical, and agricultural applications.Q: When is the MultiHead Collar Weigher Machine ideal to use in the packaging process?

A: This machine is ideal when high precision weighing, fast packaging speeds, and strict hygiene standards are required. It is commonly used during automated packaging stages in medium- to large-scale production settings, where efficiency and product consistency are paramount.Q: Where can the MultiHead Collar Weigher Machine be installed and operated?

A: The machine is designed for use in controlled environments such as food processing plants, pharmaceutical manufacturing sites, chemical packing facilities, and agricultural product distribution centers. It operates reliably within a temperature range of 5C to 40C.Q: What is the procedure for cleaning and maintaining the machine?

A: Maintenance is simplified thanks to easy-openable and removable parts. Regular cleaning after each use is recommended to maintain hygiene. The stainless steel construction ensures smooth surface cleaning, while safety interlocks prevent operation during cleaning for added operator safety.Q: How is the machine controlled and monitored during operation?

A: Operators manage the machine through a PLC-controlled system, featuring a touch screen HMI that provides real-time monitoring, parameter adjustments, and error alarms. Multi-language support further enhances ease of use across diverse operator teams.Q: What are the main benefits of using the MultiHead Collar Weigher Machine in production lines?

A: Key benefits include increased productivity through high-speed operation, reduced weighing errors, user-friendly controls, enhanced safety features, low noise output, low maintenance, and suitability for a wide range of products and packaging sizes. This improves cost-efficiency and product quality for manufacturers.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Pouch Packaging Machines Category

Vaccum Packaging Machine

Price Range 185000.00 - 195000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Other, Vaccum Packaging Machine

Computerized : No

Drive Type : Electric

Semi Automatic Packing Machine

Price Range 275000.00 - 450000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Other, Semi Automatic Packing Machine

Computerized : No

Drive Type : Electric

Mineral Water Packing Machine

Price 125000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Other, Mineral Water Packing Machine

Computerized : Yes

Drive Type : Electric

Cup Filling Machine

Price 250000 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Other, Cup Filling Machine

Computerized : Yes

Drive Type : Electric