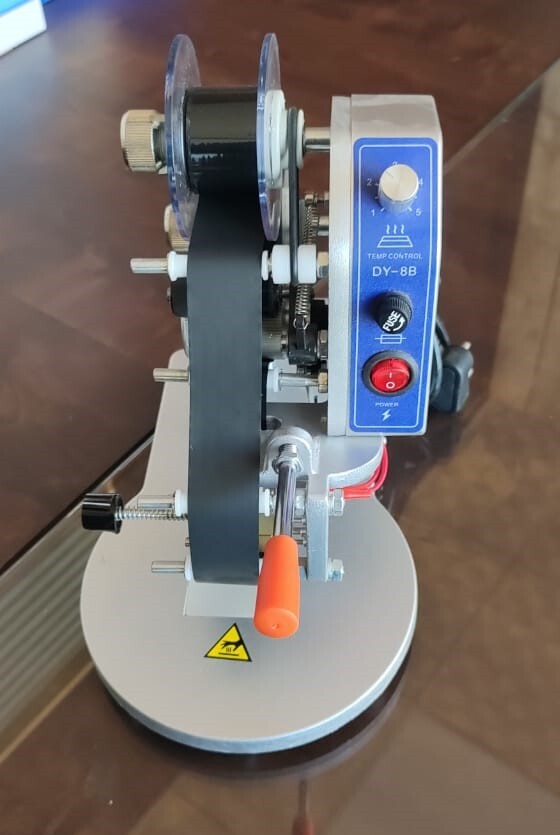

Ribbon Printing Machine

Ribbon Printing Machine Specification

- Product Type

- Ribbon Printing Machine

- Material

- Mild Steel

- Application

- Printing on ribbon, tape, and labels

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- Human Machine Interface

- Drive Type

- Electric

- Accuracy

- High printing accuracy

- Power Source

- Electric

- Voltage

- 220V

- Weight (kg)

- Approx. 24 Kg

- Dimension (L*W*H)

- 350 mm x 350 mm x 350 mm

- Capacity

- 2000-3000 pieces per day

- Feature

- Easy operation, Compact design, Durable structure

- Color

- Blue / Silver

- Operating Temperature

- Up to 300°C

- Printing Material

- Satin Ribbon, Taffeta Ribbon, Cotton Ribbon, Labels

- Max Printing Speed

- 120 impressions/minute

- Number of Printing Lines

- 1-3 Lines (Adjustable)

- Foil Color Compatibility

- Multi-color Available

- Heating Method

- Electrically Heated Type

- Print Width

- Up to 60 mm

- Impression Type

- Hot Foil Transfer

- Max Ribbon Diameter

- 80 mm

- Embossing Type

- Solid Brass Die

Ribbon Printing Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 20 Pieces Per Month

- Delivery Time

- 2-3 Days

About Ribbon Printing Machine

A ribbon printing machine is used to print designs, text, or logos on ribbons of ID cards. It can also be used in the gift and packaging industry to personalize ribbons for special occasions such as weddings, birthdays, and other events. This a thermal transfer type of ribbon printing machine that utilizes a thermal printhead to transfer ink from a ribbon onto the printing surface. The types of ribbons upon which this machine can print are satin, polyester, and more. This machine can offer a cost-effective and efficient way to create personalized ribbons with high-quality print output.

Efficient Hot Foil Printing for Versatile Ribbon Applications

Designed for both performance and convenience, this semi-automatic Ribbon Printing Machine delivers superior print quality on a range of materials, including satin, taffeta, and cotton ribbons, as well as various label types. Thanks to its electrically heated solid brass dies and multi-color foil compatibility, users benefit from vivid and durable impressions that enhance product appeal.

User-Friendly Operation with Advanced Control System

Featuring a Human Machine Interface, this machine ensures simple and precise control for operators. Printing parameters are easily adjustable, enabling one to three printing lines as required. Its compact and robust structure ensures both space efficiency and long-term reliability, making it suitable for busy production environments.

FAQs of Ribbon Printing Machine:

Q: How does the Ribbon Printing Machine achieve high printing accuracy?

A: This machine uses an electrically heated solid brass die to transfer hot foil precisely onto ribbons or labels, ensuring sharp, consistent impressions with every operation. The Human Machine Interface allows fine adjustments, contributing to its high printing accuracy.Q: What materials are compatible with this Ribbon Printing Machine?

A: It is designed to print efficiently on satin, taffeta, and cotton ribbons, as well as label tapes, making it ideal for a range of decorative or branding requirements.Q: When is it suitable to use this machine in production?

A: This machine is best suited for medium- to large-scale operations that require up to 2,0003,000 pieces per day, particularly in settings where vivid, durable ribbon printing is needed, such as garment, gift, labeling, or packaging industries.Q: Where can this Ribbon Printing Machine be installed?

A: Due to its compact design (350 mm x 350 mm x 350 mm) and moderate weight (around 24 kg), it can be installed in various factory or workshop environments with a standard 220V power supply.Q: What is the process involved in printing on ribbons using this machine?

A: First, the desired design is mounted on the brass die. The ribbon or label material is fed into the printing area. Upon activation, the machine heats the die, pressing the foil onto the material to create the impression, which can be adjusted for 13 lines per print.Q: How easy is it to operate and control the machine?

A: Operation is straightforward thanks to the Human Machine Interface. Users can quickly set printing parameters and easily switch between materials, lines, and designs, making the machine accessible even for less experienced staff.Q: What are the key benefits of using this semi-automatic Ribbon Printing Machine?

A: Key benefits include high-quality, multi-color imprinting, fast production speed, adjustable line printing, compact and durable construction, and user-friendly controlsall of which enhance productivity and product presentation.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email