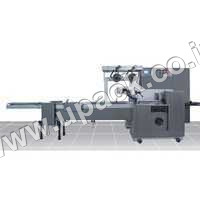

Carton Taping Machine

Carton Taping Machine Specification

- Product Type

- Carton Taping Machine

- Material

- Mild Steel

- Capacity

- Up to 20 boxes/min

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Voltage

- 220V AC

- Power

- 0.25 kW

- Conveyer Length

- 1200 mm

- Rotating Speed

- 22 m/min

- Overlap Scope

- 5565 mm

- Shift Speed

- 20 m/min

- Dimension (L*W*H)

- 1755 x 800 x 1330 mm

- Weight (kg)

- 120 kg

- Color

- Yellow & Grey

- Operation Mode

- Push Button & Manual Adjustment

- Tape Width

- 36 mm, 48 mm, 60 mm

- Conveyer Type

- Roller Conveyor

- Adhesive Tape Used

- BOPP/Adhesive Tape

- Sealing Height

- 110500 mm

- Min. Carton Size (L*W*H)

- 150 x 180 x 110 mm

- Frame Structure

- Heavy Duty Welded Frame

- Application

- Sealing Carton Boxes (Top & Bottom)

- Driven Type

- Motorized

- Max. Carton Size (L*W*H)

- x 500 x 500 mm

- Noise Level

- Less than 75 dB

- Sealing Width

- 150500 mm

About Carton Taping Machine

Carton taping machine is applicable for the top as well as bottom sealing of carton boxes. The machine has many adjustable features and can deal with various size of cartons. It has a carton holding roller as well as adjustable conveyor height. Carton taping machine can be effortlessly fixed on the castor wheels. Suited for the sealing as well as taping of bulk carton supply, this is extensively demanded in the packaging industry. The sealing pressure can be adjusted, whenever needed. Also, it has adjustable arms, which are robust enough to manage the heavy loads.

Efficient Carton Sealing Performance

This semi-automatic carton taping machine delivers rapid box sealing, processing up to 20 cartons per minute with precise top and bottom tape application. The motorized roller conveyor and robust welded frame ensure stability and long-term durability, making it an excellent asset for busy packaging lines.

Versatile Operation and Adjustment

Thanks to its push button operation and manual adjustment, this machine seamlessly adapts to different carton sizes. The adjustable tape width options and sealing dimensions facilitate packaging various box specifications, optimizing workflow in industrial and commercial settings.

Built for Reliability and Safety

Constructed from heavy-duty mild steel, the machine boasts a reliable welded frame. Its low noise level of less than 75 dB enhances workplace comfort, while the semi-automatic grade supports safe, supervised operation. The yellow & grey design adds a modern touch to any facility.

FAQs of Carton Taping Machine:

Q: How does the carton taping machine accommodate different box sizes?

A: The machine features adjustable sealing height (110500 mm) and width (150500 mm), as well as manual adjustment modes, allowing it to handle various carton dimensions from a minimum of 150 x 180 x 110 mm up to maximum sizes of x 500 x 500 mm.Q: What type of adhesive tape is best suited for this machine?

A: This taping machine is compatible with BOPP and adhesive tapes ranging from 36 mm to 60 mm in width, providing secure sealing for both top and bottom of the cartons.Q: When is manual adjustment necessary during operation?

A: Manual adjustment is required when changing carton sizes or tape widths, optimizing the machine for each batch and ensuring proper sealing efficiency and tape application.Q: Where is this carton taping machine commonly used?

A: It is widely utilized in Indian manufacturing, distribution, and export facilities where efficient carton sealing is essential, such as warehouses, logistics centers, and packing stations.Q: What benefits does the heavy duty welded frame offer?

A: The robust welded frame, constructed from mild steel, offers enhanced durability and stability, handling rigorous workloads and supporting continuous high-speed operation without deformation.Q: How does the roller conveyor enhance the sealing process?

A: The motorized roller conveyor ensures smooth and consistent box movement, allowing for quick, even tape application and keeping throughput high at speeds up to 22 meters per minute.Q: What is the process for operating the machine?

A: Operation involves loading cartons onto the conveyor, using the push button to start the motorized system, and adjusting settings for carton dimensions. The machine then seals both top and bottom flaps efficiently.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Carton Tapping Machines Category

Reel Stretch Wrapping Machine

Price Range 350000.00 - 360000.00 INR

Minimum Order Quantity : 1 Piece

Product Type : Reel Stretch Wrapping Machine

Computerized : Yes

Automatic Grade : Automatic

Toilet Soap Wrapping Machine

Price Range 550000.00 - 1000000.00 INR

Minimum Order Quantity : 1 Piece

Product Type : Toilet Soap Wrapping Machine

Computerized : Yes

Automatic Grade : Automatic

Carton Wrapping Machine

Price Range 85000.00 - 140000.00 INR

Minimum Order Quantity : 1 Piece

Product Type : Carton Wrapping Machine

Computerized : Yes

Automatic Grade : Automatic

Soap Wrapping Machine

Price 280000.00 INR

Minimum Order Quantity : 1 Unit

Product Type : Soap Wrapping Machine

Computerized : Yes

Automatic Grade : Automatic