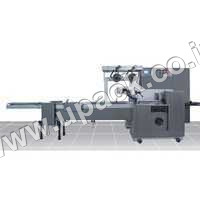

Soap Wrapping Machine

Soap Wrapping Machine Specification

- Product Type

- Soap Wrapping Machine

- Material

- Stainless Steel

- Capacity

- 2000-3000 soaps/hour

- Computerized

- Yes

- Automatic Grade

- Automatic

- Voltage

- 220-240 V

- Power

- 3.5 kW

- Conveyer Length

- 1800 mm

- Rotating Speed

- Variable (up to 90 packs/min)

- Overlap Scope

- 5-20 mm

- Shift Speed

- Adjustable

- Dimension (L*W*H)

- 3400 mm x 850 mm x 1650 mm

- Weight (kg)

- Approx. 750 kg

- Color

- Metallic Grey

- Operator Interface

- Touch Screen PLC

- Changeover Time

- Less than 20 minutes

- Temperature Range

- Ambient to 200°C

- Noise Level

- <72 dB

- Cooling System

- Air-cooled

- Soap Shape Compatibility

- Round, Oval, Rectangular

- Main Drive

- Servo Motor Driven

- Maintenance Interval

- Every 6 months

- Packing Style

- Lateral Sealing with Fin Seal

- Max Soap Size

- Length 120 mm x Width 70 mm x Height 50 mm

- Packing Range

- Multipack & Single Pack

- Safety Features

- Emergency Stop Button, Overload Protection

- Film Type

- Cellophane / BOPP Film

About Soap Wrapping Machine

The Soap Wrapping Machine is an exclusively designed machine, which is used to wrap the soap bars of rectangular as well as oval shapes. The machine is capable to perform its function without the use of side band. In addition, it has stability in its operation. The wrapping style of Soap Wrapping Machine is known as double-point end fold. The machine can save a lot of money. It is accessible with an automated in feed soap system so as to feed the stamped soap bars. Provided machine provide a good production rate and can wrap hundreds of soaps in every minute.

Versatile Film Compatibility

This machine is designed to operate with both Cellophane and BOPP film, offering flexibility in packaging material selection. Its capability to handle a broad size range and various soap shapes round, oval, or rectangular makes it suitable for diverse product requirements in the soap industry.

Efficient and User-Friendly Operation

The modern touch screen PLC interface enhances usability, allowing operators to program and monitor the machine conveniently. Changeover between different soap types or pack styles is accomplished in less than 20 minutes, ensuring minimal downtime and maximum productivity in fast-paced environments.

Safety and Durability

Safety is paramount, with essential features like an emergency stop button and overload protection. Constructed from robust stainless steel, this machine is built for long-term reliability, with a recommended maintenance interval of every six months to ensure optimal performance.

FAQs of Soap Wrapping Machine:

Q: How does the soap wrapping machine accommodate different soap shapes?

A: The machine is engineered with adaptable guides and change parts, allowing it to handle round, oval, and rectangular soaps within the specified maximum dimensions. Quick changeover features enable seamless transition between types, minimizing production interruptions.Q: What is the process for switching between single pack and multipack formats?

A: Switching between single and multipack packing styles involves selecting the desired option on the touch screen PLC and adjusting mechanical settings as indicated by the user guide. The process typically takes less than 20 minutes, making it efficient for varying production needs.Q: When should routine maintenance be performed, and what does it involve?

A: Routine maintenance is recommended every six months. Regular servicing includes checking the drive system, verifying film alignment, inspecting temperature controls, and ensuring all safety devices function correctly. Preventive care helps maintain consistent high output and machine longevity.Q: Where is this machine typically utilized, and who are its primary users?

A: This model is widely adopted by distributors, exporters, manufacturers, suppliers, and traders in India, especially those handling medium to large volumes. Its versatility and robust capabilities make it a favored choice in soap manufacturing facilities.Q: What are the benefits of using a touch screen PLC with this wrapping machine?

A: The touch screen PLC simplifies operator control, offering intuitive navigation through settings and diagnostics. This reduces training times, streamlines operation, and enhances error detection and resolution, contributing to higher efficiency and fewer production delays.Q: How does the machine ensure safe operation during production?

A: Safety is assured through integrated features such as an emergency stop button and overload protection system. The air-cooled design keeps the system stable, while the stainless steel construction provides durability and hygiene.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Carton Tapping Machines Category

Reel Stretch Wrapping Machine

Price Range 350000.00 - 360000.00 INR

Minimum Order Quantity : 1 Piece

Product Type : Reel Stretch Wrapping Machine

Automatic Grade : Automatic

Computerized : Yes

Toilet Soap Wrapping Machine

Price Range 550000.00 - 1000000.00 INR

Minimum Order Quantity : 1 Piece

Product Type : Toilet Soap Wrapping Machine

Automatic Grade : Automatic

Computerized : Yes

Carton Wrapping Machine

Price Range 85000.00 - 140000.00 INR

Minimum Order Quantity : 1 Piece

Product Type : Carton Wrapping Machine

Automatic Grade : Automatic

Computerized : Yes

Carton Taping Machine

Price 82000 INR

Minimum Order Quantity : 1 Piece

Product Type : Carton Taping Machine

Automatic Grade : SemiAutomatic

Computerized : No