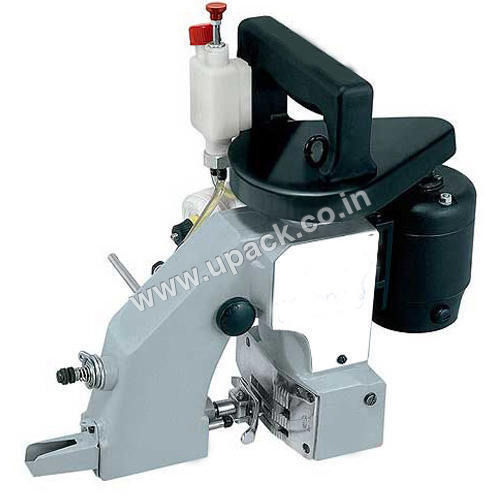

Continuous Bag Sealer

Continuous Bag Sealer Specification

- Product Type

- Continuous Bag Sealer

- General Use

- Sealing Plastic Bags and Pouches

- Capacity

- Up to 12 meters/min

- Weight (kg)

- 25 kg

- Automatic Grade

- Semi Automatic

- Type

- Horizontal

- Drive Type

- Electric

- Bag Type

- Plastic Bags (PE, PP, Laminated Films)

- Computerized

- No

- Power

- 500W

- Voltage

- 220V/50Hz

- Heater

- Yes

- Material

- Mild Steel/ Stainless Steel Body

- Dimension (L*W*H)

- 840 x 380 x 320 mm

- Color

- White with Green (as per image)

- Cooling System

- Fan Cooled

- Operation Mode

- Manual & Semi automatic

- Sealing Width

- 5-10 mm

- Printing Capability

- Yes, with ink printing device

- Temperature Range

- 0 - 300°C adjustable

- Conveyor Load Capacity

- Up to 3 kg

- Suitable For

- Food, Pharmaceuticals, Chemical Industry Packaging

- Noise Level

- Low

- Speed Control

- Variable Speed Adjustment

- Sealing Length

- Unlimited (continuous)

Continuous Bag Sealer Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 50 Pieces Per Month

- Delivery Time

- 2-3 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Domestic Market

- All India

About Continuous Bag Sealer

Continuous Bag Sealer is an industrial appliance which is used to join thermoplastics films by the application of heat and high pressure. It is runs on the standard electrical voltage of 220 volts for the generation of heat into the resistive element placed at the middle of the setup. It is provided with a conveyor on which plastic pouches are placed and their open end which is to be sealed is placed in between the heating metal elements. As the belt of the continuous bag sealer moves it drives the bags from one end of the high temperature strip to the other to provide an insulated seal.Efficient and Versatile Sealing

Crafted for continuous high-volume operations, this horizontal bag sealer ensures secure seals on a wide range of plastic and laminated films. With its variable speed adjustment and powerful 500W heater, it accommodates diverse packaging needs, making it ideal for food, pharmaceutical, and chemical industries.

Smart Temperature & Speed Control

Designed for precision, the sealer lets users adjust the sealing temperature from 0 to 300C and fine-tune the conveyor speed. This flexibility enables optimal performance for different bag types and thicknesses, delivering strong, uniform seals every time.

Integrated Printing for Better Traceability

The built-in ink printing device simplifies labeling by marking essential details such as date, batch number, or logos directly onto the bag surface during sealingstreamlining compliance and improving traceability for exported goods.

FAQs of Continuous Bag Sealer:

Q: How do I adjust the sealing width and temperature on this bag sealer?

A: You can set the sealing width between 5-10 mm using the machines dedicated adjustment knob or lever. Temperature control is easily managed via a built-in dial, allowing you to select the ideal level within a range of 0 - 300C to suit the bag material and thickness.Q: What types of bags and industries is this bag sealer suitable for?

A: This sealer is designed for a variety of plastic bags, including PE, PP, and laminated films. Its particularly suited for industries like food processing, pharmaceuticals, and chemicals, ensuring reliable, airtight packaging.Q: When should I use the printing function, and how does it work?

A: Use the integrated ink printing device whenever you need to add product details, batch numbers, or manufacturing dates to your packaging. The printer automatically marks bags as they pass through the sealing area, making traceability straightforward.Q: Where can this continuous bag sealer be operated safely?

A: Given its compact size and robust construction, the sealer is suitable for installation in small workshops, factories, or packaging facilities. Ensure the unit is placed on a flat, stable surface with access to a 220V/50Hz power supply.Q: What is the process for sealing and printing on plastic pouches?

A: To seal and print, place filled bags on the conveyor. Adjust the sealing width, temperature, and speed for your material. The machine will guide the bags through the heater for sealing and fan for cooling, concurrently printing any required details. Bags exit fully sealed and printed, ready for distribution.Q: What benefits does this continuous bag sealer offer manufacturers and suppliers?

A: This machine increases productivity by sealing bags at speeds of up to 12 meters per minute. Its low noise operation, variable controls, durable construction, and in-line printing feature offer consistent results and reduced labor, making it invaluable for Indian exporters, distributors, and manufacturers.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Bag Closing Machine Category

Poly Bag Sealer Machine

Price 1500 INR / Piece

Minimum Order Quantity : 1 Piece

General Use : Sealing

Material : Metal

Type : Sealing Machine

Product Type : Bag Sealer Machine